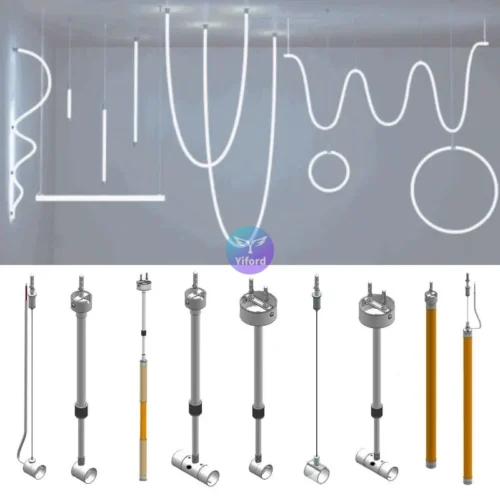

Suspended Mounting

Suspended mount, generally can also be used for recessed mount, surface mount, Yiford is with variety of installation accessories can be choosed.

Whatever your domestic or commercial lighting project, our easy-to-install suspendable LED profiles offer a stylish look and finish to complement the aesthetic in your task zones,

Round Tube

Round Tube

Topview Tube

Topview Tube

Sideview Tube

Sideview Tube

With Fringe

With Fringe

Black Tube

Black Tube

Light Accessories

Light Accessories

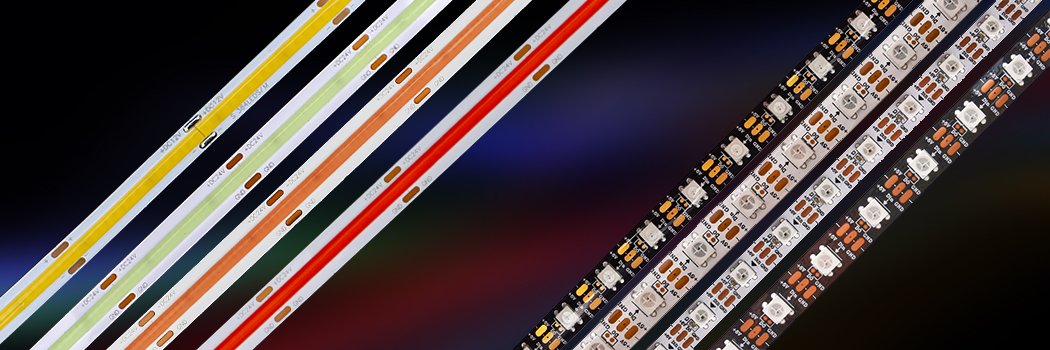

COB LED Strip Lights

COB LED Strip Lights