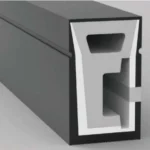

Half cover silicone sleeve

The half-cover silicone sleeve also called split-type silicone sleeve, it is different from the full-sleeve type. Its bottom is hollowed out, and the hollowed-out space is where the light strip is installed and hidden.

No need to enter the light strip first, use it immediately after slotting, with built-in ribs, no need to seal

Round Tube

Round Tube

Topview Tube

Topview Tube

Sideview Tube

Sideview Tube

With Fringe

With Fringe

Black Tube

Black Tube

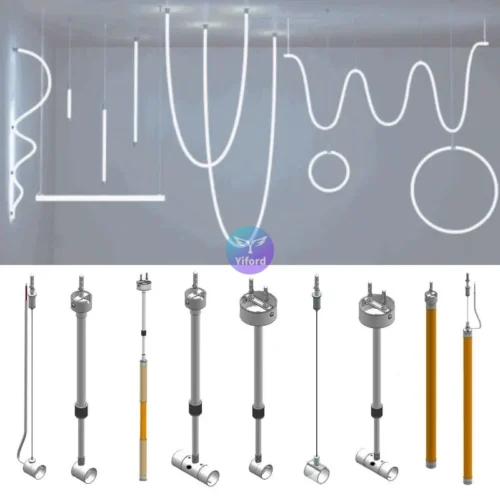

Light Accessories

Light Accessories

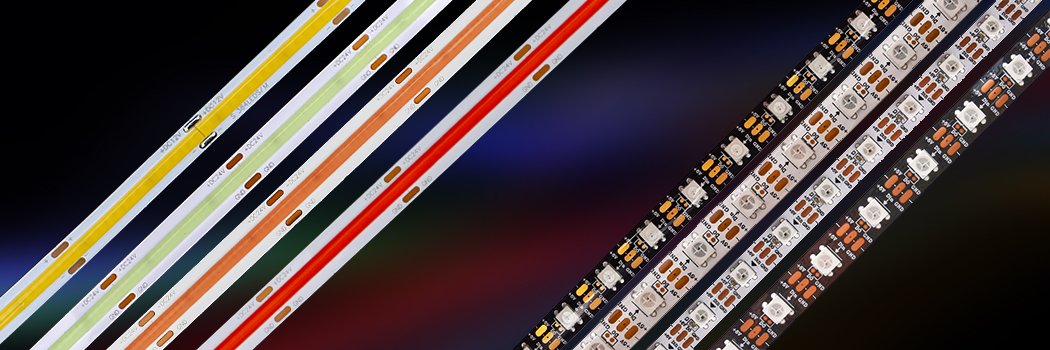

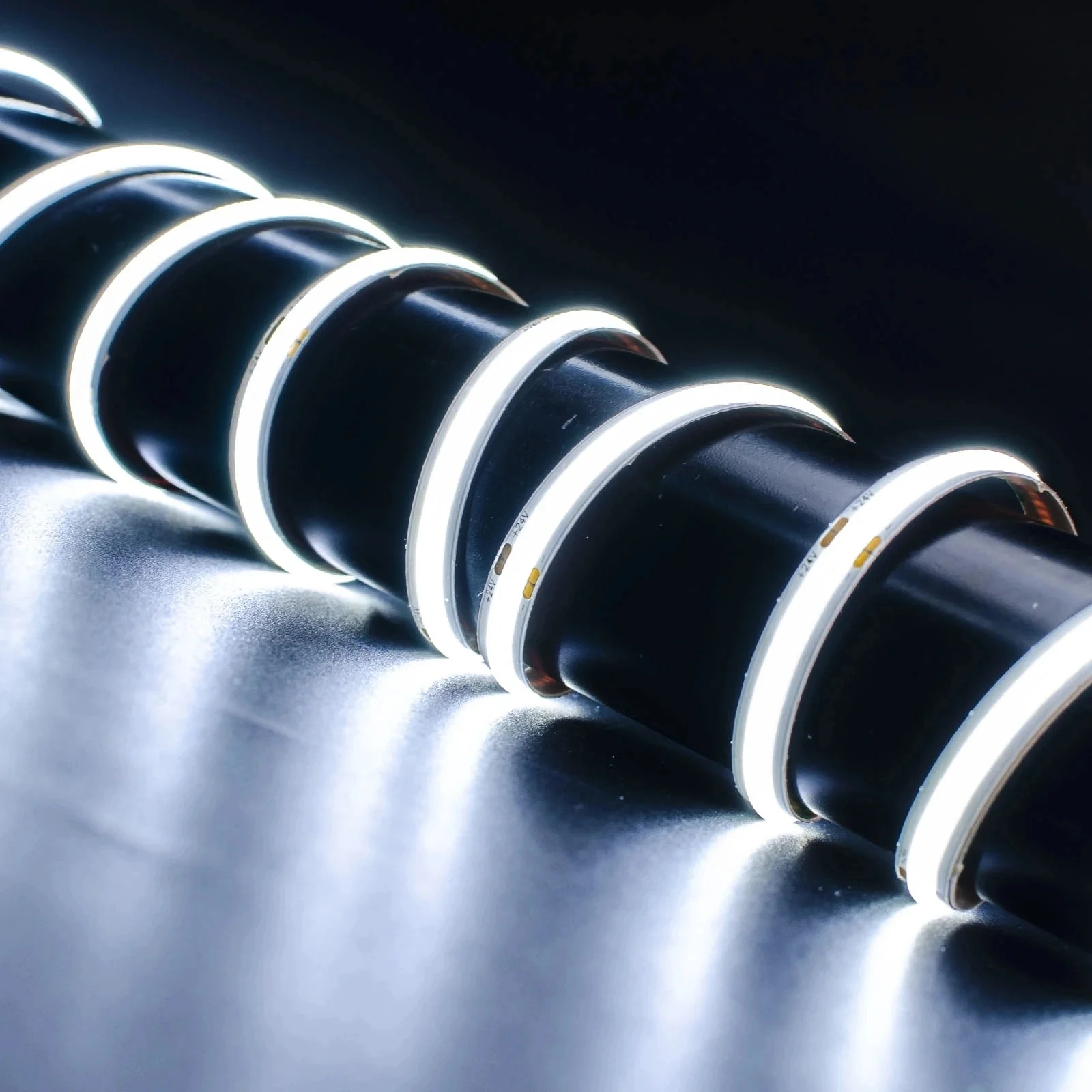

COB LED Strip Lights

COB LED Strip Lights