power supply

witching power supplies convert AC 110V or 220V line voltage to a low DC constant voltage output; matching the input voltage specifications of LED drivers.

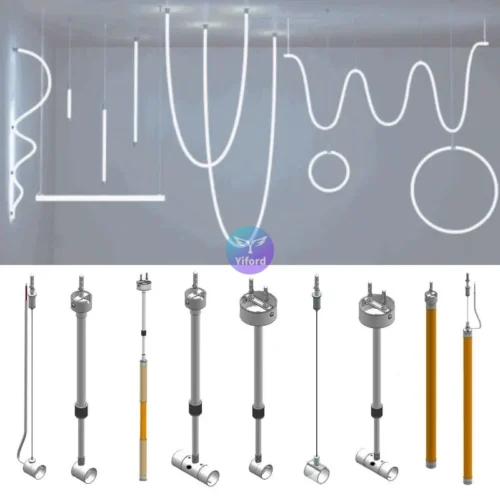

Neon LED light strips innovate through material science and functional integration, overcoming traditional LED limitations in protection, safety, and adaptability. Their multi-scene compatibility and cost efficiency make them a pragmatic yet aesthetic solution for modern lighting design.

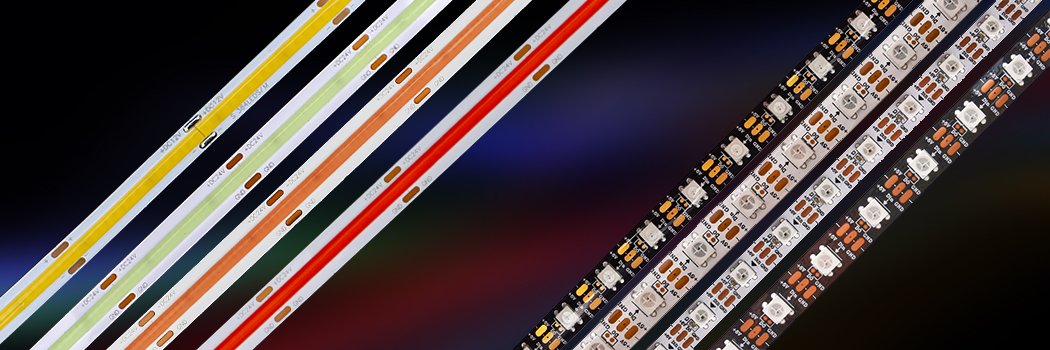

LED strip lights are versatile lighting solutions that offer energy efficiency, long lifespan, and customizable designs. They come in two main types: COB (Chip-on-Board) LED strip lights, which provide a continuous, uniform light output ideal for seamless applications, and SMD (Surface-Mounted Device) LED strip lights, known for their flexibility and variety in brightness and color options. Both types are easy to install and can be used for accent lighting, task lighting, or decorative purposes, enhancing any space while reducing electricity costs.

YIFORD offers a wide range of solderless connectors designed for LED strip lights, simplifying installation without the need for soldering. Our product lineup includes board-to-board, board-to-wire, wire-to-wire, L-shaped, and T-shaped connectors, with hundreds of styles available. Compatible with nearly all widths and models of LED strip lights on the market, our connectors ensure reliable connections for both DIY enthusiasts and professionals.

Silicone light strips are very soft and can be bent, twisted, and stretched freely, suitable for complex design and installation environments. It has strong weather resistance, is not easy to crack, and has a long service life. Silicone light strips are usually designed with low voltage, which improves the safety of use. In addition, silicone material itself has characteristics such as fire resistance, gas corrosion resistance, and UV protection, which can work stably in harsh environments.

Light Accessories

Light Accessories

The LED controller is a chip that processes and controls the switches at various positions in the LED light circuit. The controller controls the driving circuit according to the pre-set program to make the LED array emit light in a regular manner.

If you want to add some brightness to the room or change the shadow of the space by yourself, LED strips are your best choice. Even if you don’t have any electrical experience, you can easily set it up.

How to install the COB led strips? A successful installation only requires a few simple steps. First, determine your suitable length of LED strip and matching power supply. Remember to test before installation.

Although soldering is a more durable way to connect LED strips and connectors, most installers don’t want to use tools such as soldering irons and tin wires. Yiford has developed various connectors for COB strips. You can manually connect a variety of light strips, fix the LED in place with its double-sided adhesive, and then connect the power supply to start enjoying your lighting atmosphere.

The first step: prepare related materials, tools, connectors, etc.

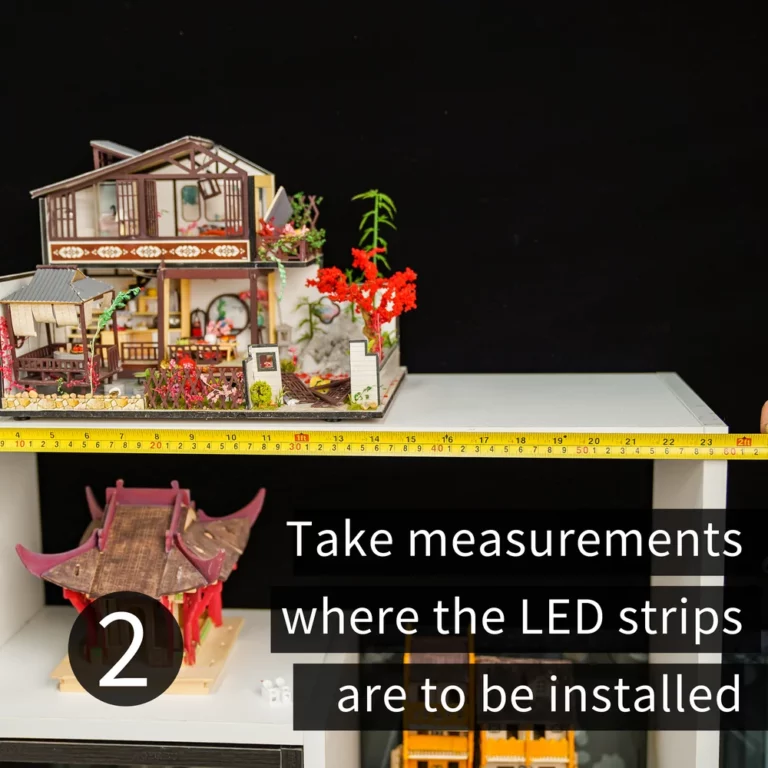

Step 2: Measure the length of the installation area

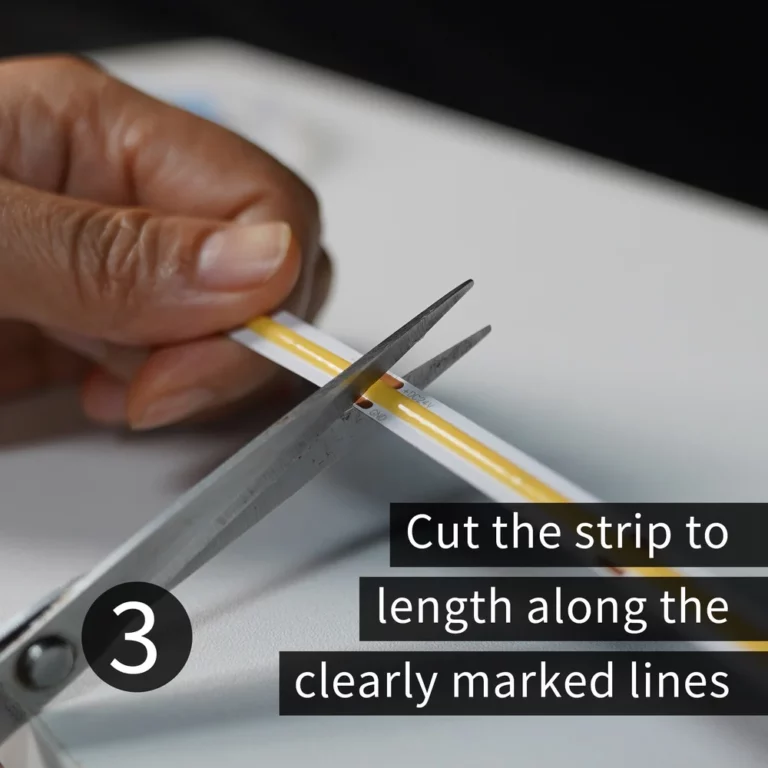

Step 3: Cut the light strip lights

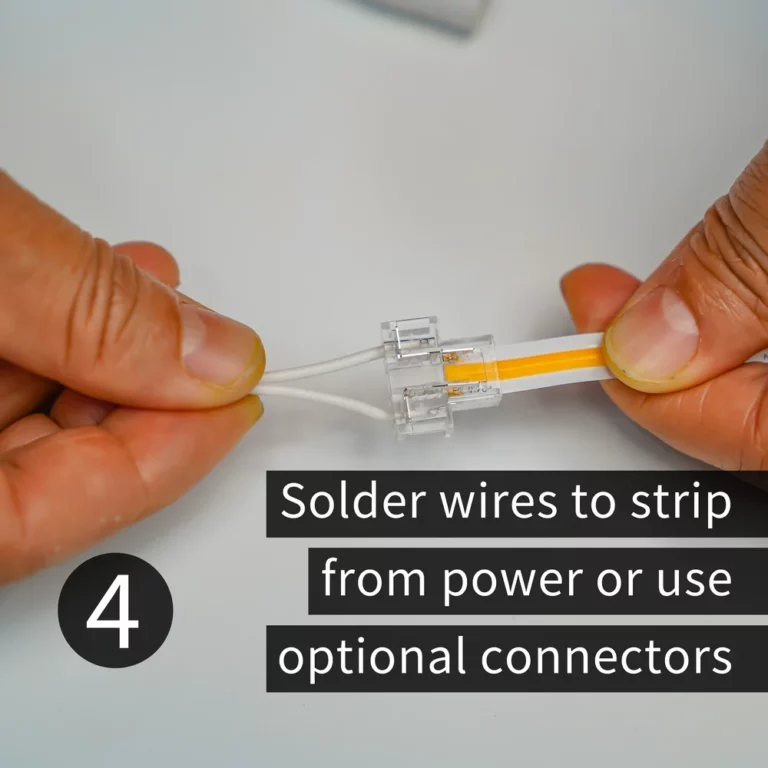

Step 4: Wiring the lighting strip

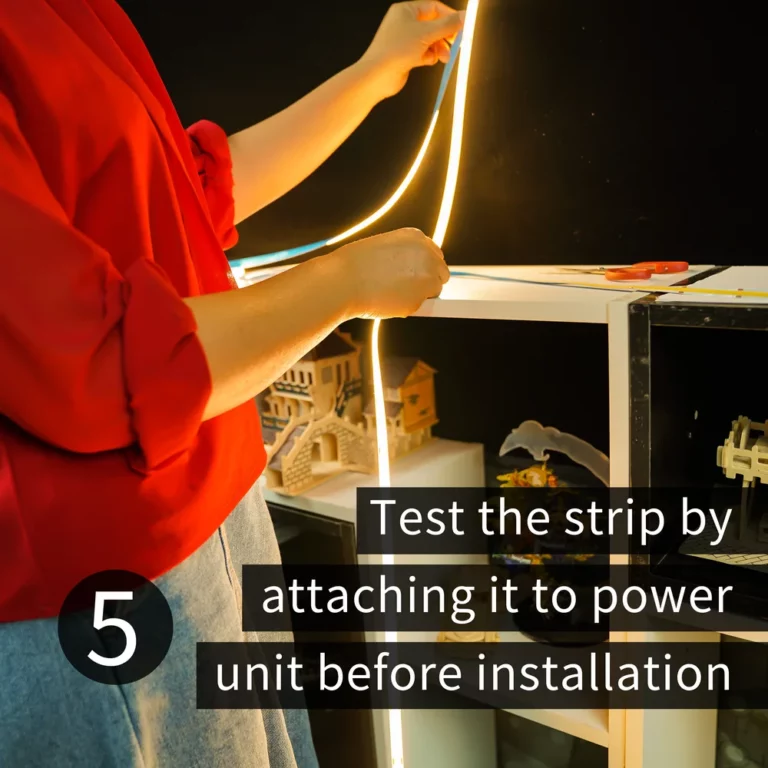

Step 5: Test the light strips

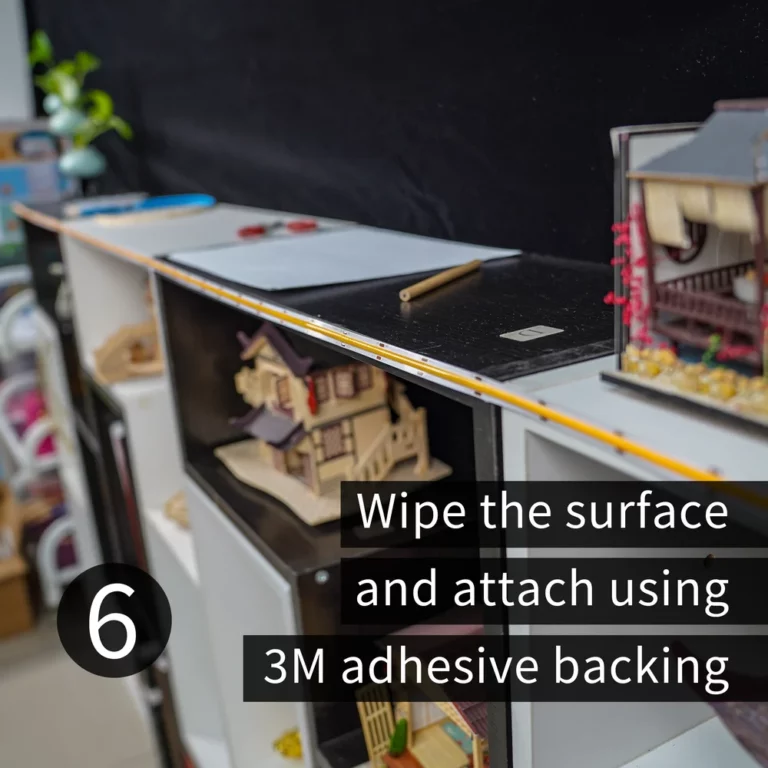

Step 6: Clean and attach the led lighting

Step 7: Connect the led controller or led dimmer

Step 8: finally connect the led power supply, test OK

Prepare the materials you need What you need for cutting and re-connect led light strips? If you buy an LED strip kit, it will have everything you need to install the light. For more complex jobs that require the use of single parts, you need:

COB light strip, a roll of 5 meters is the standard packaging size of conventional light strips.

LED light strips connector

Dimmer or controller

Power supply or converter

At the same time, you also need scissors or pliers for cutting the light strip, and a tape measure for measuring the length.

You may also need more materials, such as

Connector for COB LED strip

Aluminum channel or track for fixing strip lights

Or silicone led channel system for led strips

Diffusion cover for hiding or protecting COB light strip

Screws and brackets for fixing the channel to the surface

How to install the cob led strips light? When placing LED strip lighting equipment under your counter, shelf or recess, it is very important to check the LED lighting equipment before any setting. Before cutting any lighting equipment or attaching them to any floor, please observe where they are installed. Lay out everything to create a mock installation to make sure you have all the necessities.

Double check your lighting before cutting or putting in

Unroll the LED strip from the plastic reel

Connect the uncut lamp to the power source and activate the intensity power source

The strips should be gentle. If they don’t, please check your connection

Ask yourself “Are there enough lights?”, “Do I need a dimmer”, “Is the color the best for my software?”, “Are all the LED lights lit and working well?” “

When the lighting equipment is working well and you are sure that you have determined the appropriate color temperature and brightness for your adventure, proceed to step two.

Install the cob led strips light, You should measure the length of the location where you plan to place the lights to make sure you buy enough. It is also important to choose the correct LED power supply before starting the project. This will depend on how long your strip lighting will last. If you just want to place a light bar under a bar or kitchen cabinet, the LED light bar kit will do.

Install the cob led strips light, Cutting led strips light is easy, before beginning any setup of the system, it is critical to measure carefully to determine how long it takes. Lights should also be placed at the corners. The COB light has the smallest cutting unit. It is recommended to use a bit longer than the actual one. If you reserve a longer, you can quickly cut it shorter, but if you reserve a short one and want to extend it, it will not be so convenient. Be sure to cut along the cutting line. Otherwise, the chips of the last group of lights cannot form a loop and cannot emit light normally. tunable white led strip lighting and RGB light strips are same like cut like this. they have the cut mark on the print circult board, very easy to find it.

Install the cob led strips light, If the COB light strip is cut and there is no main connecting wire, you can solder a set of wires with a soldering money, or you can use this "board-to-wire connector" to insert the COB light strip while inserting the stripped wire , You can connect the wire to the COB light strip.

Install the cob led strips, To connect the primary stage of the lamp to the dimmer and intensity power supply, we hope to connect some duration low-voltage extension cords to the stop of the main operating LED lighting fixture. Here we may use a connector. This connector acts as a bridge. The usage is also very simple. Insert the corresponding two sets of wires into the small holes. There are metal pieces in the holes to connect the two sets of wires. Remember that the positive pole is to the positive wire, and the negative pole is to the negative wire.

install the cob led strips, If there are corners, you can use this connector, two-channel and three-channel circuit boards, and you can easily connect multiple sets of light strips

lnstall the cob led strips light, Clean the surface to be installed so that the adhesive of the LED strip can be better bonded together. 3M glue can stick to most non-porous and flat surfaces. For procedures under concrete or very difficult fabrics, adhesives can be used. After cleaning, tear off the adhesive layer of the COB light strip, while tearing off the adhesive, push the light strip forward to glue it. led strip light installation could use the back 3M adhesive tape, also could use the mounting clips. it depends on how and where will you install the led strip lighting.

This step is very important. power led strips with the adapter, Be sure to check the light strip before installation. Connect the light strip to the led power supply and test to see if the color is correct, the connection is firm, and all lights are normal. If not, check the cause and correct it.

Install the controller on the wall, connect the IN mark to the power supply, and connect the OUT mark to the light strip.

The last step is the easiest and the most comforting step in the entire method. Now all you have to do is turn on the power switch, adjust the dimmer to the brightness you decide, the controller gets your favorite program, and then experience your new LED light and feel the beautiful atmosphere.

witching power supplies convert AC 110V or 220V line voltage to a low DC constant voltage output; matching the input voltage specifications of LED drivers.

led aluminum channels, inside is the led strip light or led light bar.

Install the led cabinet lights directly under neath your cabinet ,silluminate the countertops below for safer, more functional for food prepare and brighter.

architectural lighting is the intersection of art (architecture) and technology (lighting). Buildings that are illuminated or illuminated can be commercial or residential. Other areas of endeavor, such as design, also came into play.