Recessed installation

Small size recessed mounting aluminum profiles led can be installed with a thermo conductive adhesive tape or glue, and bigger models has own independent mounting brackets. each led aluminum channel has the install bracket or clips for installation, you can chooise it base on how will your lighting project designed.

Round Tube

Round Tube

Topview Tube

Topview Tube

Sideview Tube

Sideview Tube

With Fringe

With Fringe

Black Tube

Black Tube

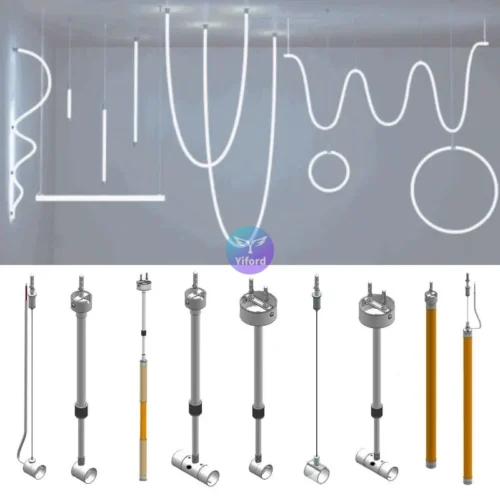

Light Accessories

Light Accessories

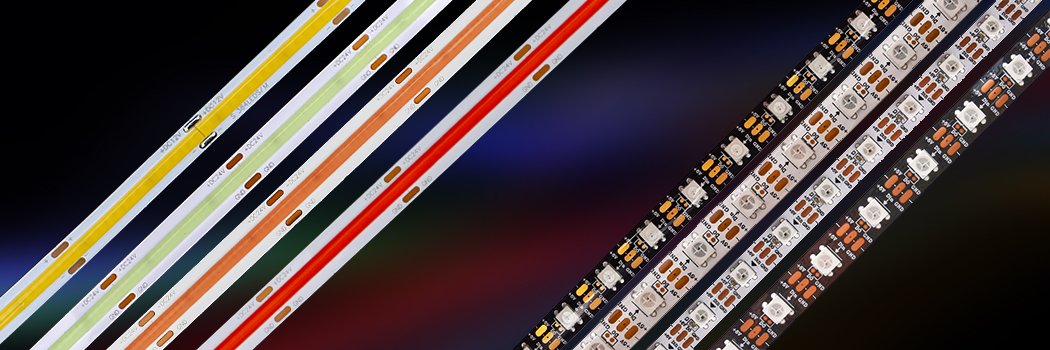

COB LED Strip Lights

COB LED Strip Lights