What should I pay attention to when customizing LED strips?

Because of its high brightness and low energy consumption, LED light strips are often used in building decoration, advertising light boxes, jewelry display stands and other constant-light equipment, but what aspects should be considered when customizing LED Strips light?

1. はんだ接合部を見てください。

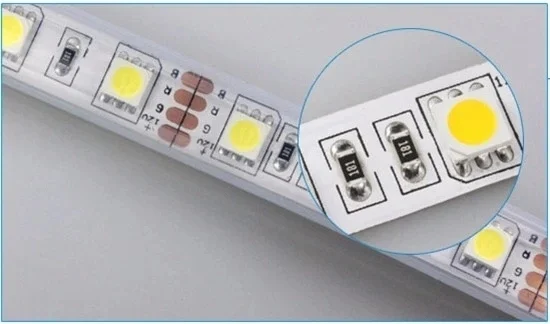

The LED light bar produced by the regular LED light bar manufacturer is produced by SMT chip technology, using solder paste and reflow soldering process. Therefore, the solder joints on the LED light bar are relatively smooth and the amount of solder is small, and the solder joints extend from the FPC pad to the LED electrode in an arc shape. However, the solder joints of the fake version of LED light bars are not uniform, and most of them appear as a dot to cover the solder feet, and at the same time there will be different degrees of tin tips, which is a typical phenomenon of manual soldering.

2. FPCの品質を見てください。

FPCは、銅と圧延銅の2種類に分けられます。銅張板の銅箔がはみ出しています。よく見るとパッドとFPCの接続部分からわかります。圧延された銅はFPCに密接に接続されており、パッドが脱落することなく自由に曲げることができます。銅張板を曲げすぎるとパッドが脱落し、メンテナンス時の温度が高すぎるとパッドが脱落します。

3. LED ストリップの表面の清浄度を確認します。

If the LED light bar produced by SMT process is used, the cleanliness of the surface is very good, and no impurities and stains can be seen. However, if the counterfeit LED light bar is produced by hand soldering process, no matter how it is cleaned, there will be stains and cleaning marks on the surface, and there will be flux and tin residue on the surface of the FPC.